COMET-Programme

The strategic objectives of COMET are: developing new expertise by initiating and supporting long-term research co-operations between science and industry in top-level research, and extablishing and securing the technological leadership of companies. By advancing and bundling exting strengths and by integrating international research expertise Austria is to be strengthened as a research location for the long term.

The competence center BEST - Bioenergy and Sustainable Technologies GmbH is funded by BMIMI, BMWET and the federal states Vienna, Lower Austria und Styria within the scope of COMET - Competence Centers for Excellent Technologies. The program COMET is managed by the FFG.

As a link between academic research and industrial technology development, our vision is to develop and demonstrate sustainable and circular biorefinery processes and technologies for producing green gases, green liquid fuels, and green products, all of which will support the transition to a climate-neutral, zero-fossil-carbon economy. Consequently, the resource basis will be extended to include organic residues, wastes, and carbon dioxide. Conversion technologies will be enhanced or redesigned to ensure their efficient and economical operation, and to allow the value cycles based on new feedstocks to be integrated into the system. By using our excellent experimental facilities, ranging from lab to pilot and demonstration scale plants, our goal is to conduct applied research of the highest scientific quality.

We apply advanced digital methods for technology development, and for the basic automation, optimization, and monitoring of the operation of individual technologies and entire plants. With the help of holistic and technology-neutral planning tools, we ensure that biorefineries and energy supply technologies are optimally integrated into a sustainable, renewable energy system.

HYDROGEN FROM SOLID BIOGENIC RESIDUES

In the project BIO-LOOP, innovative technologies are combined to develop a new concept for producing green hydrogen from biomass and solid waste.

In view of the climate goals, Chemical Looping (CL) processes for producing green hydrogen represent a promising alternative to conventional methods. In this process, steam is passed over solids, so-called oxygen carriers, to release oxygen atoms and produce pure hydrogen. To achieve this, oxygen atoms must first be removed from the oxygen carrier, usually metal oxides. These process steps of reduction and oxidation are carried out as a so-called chemical loop. In the present concept, the reduction potential of the gas generated by the thermochemical conversion of renewable feedstocks, known as fixed-bed gasification, is used for this purpose. Unlike complete combustion, the gas obtained after the gasification process is rich in CO, H2, and CH4 and has the ability to remove oxygen atoms from the oxygen carrier (reduction potential).

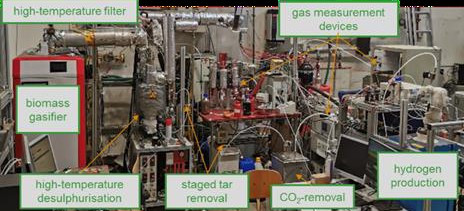

Within the project BIO-LOOP, the coupling of the gasification system and the CL hydrogen production system was implemented on a pilot scale to conduct experimental investigations under near-industrial conditions. Initially, impurities (dust, sulphur components, higher hydrocarbon components) were removed from the generated raw gas and the CO2 content was reduced (standard configuration). To increase the reduction potential of the gas, the setup was supplemented with an additional post-reaction zone (reformer) immediately after the gasifier. Furthermore, the influence of an additional steam injection was investigated. To evaluate the overall concept, the process efficiency and the purity of the produced hydrogen were determined. For this purpose, the test setup is equipped with appropriate online and offline gas analysis devices (NDIR, μ-GC, FTIR, and Tar-SPE).

Results

The high CO concentration (> 30 vol%) of the reduction gas from the biomass gasification process, and varying gas qualities, initially caused carbon deposits, especially in transition zones before and immediately at the entry of the Chemical Loop reactor. Very high impurities of CO and CO2 in the product hydrogen (>4000 ppm) were the consequence.

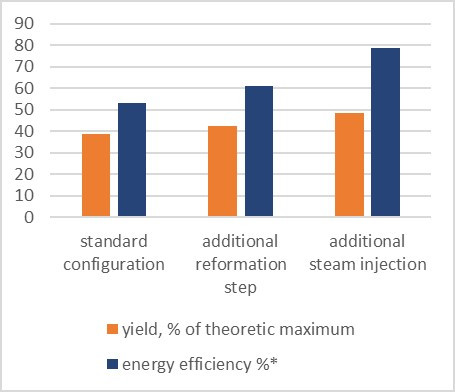

With changing the setup by inserting a reforming unit immediately after the gasification zone and with an additional steam injection unit, a final hydrogen purity of 99.9922 vol% was achieved (impurities <100 ppm). Similarly, the produced hydrogen yield and process efficiency could be significantly improved. A comparison of the three setup configurations is shown in Figure 1. With a gasification conversion efficiency of 78% (cold gas efficiency, using dry wood chips) an overall hydrogen to biomass conversion efficiency of over 60% was achieved in the best-case configuration.

Hydrogen yield and energy efficiency for three investigated set up configurations.

*energy content of H2 produced to energy content of converted inlet gas

Next steps

In the final year of the project, a techno-economic analysis based on the latest results will be carried out to assess the potential for an industrial implementation of the novel hydrogen production concept. Furthermore, the possibility of improving the reduction potential of the produced biomass gasification gas will be studied. For this purpose, further experimental tests adding steam/oxygen-mixtures to the gasification process will be done.

Partner

- TU Graz (ITE, CEET)

- TU Wien

- NIC Ljubljana

- CSIC Spain

- Chalmers University of Technology

- Aichernig Engineering GmbH

- AVL List GmbH

- Christof Industries Austria GmbH

- Rouge H2 Engineering GmbH

- SW-Energie Technik GmbH

- TG Mess-, Steuer- und Regeltechnik GmbH

- Rohkraft- Ing. Karl Pfiehl GmbH

Contact

Kai SCHULZE

kai.schulze@best-research.eu