Process Analysis and Simulation

Our activities focus on the analysis of industrial thermochemical processes based on numerical simulation methods, customized laboratory analyses, in-situ measurements at industrial plants as well as model-based evaluations. The close interaction of experimental analytics with simulation enables a comprehensive process analysis as well as a continuous development of the measurement methods and models used.

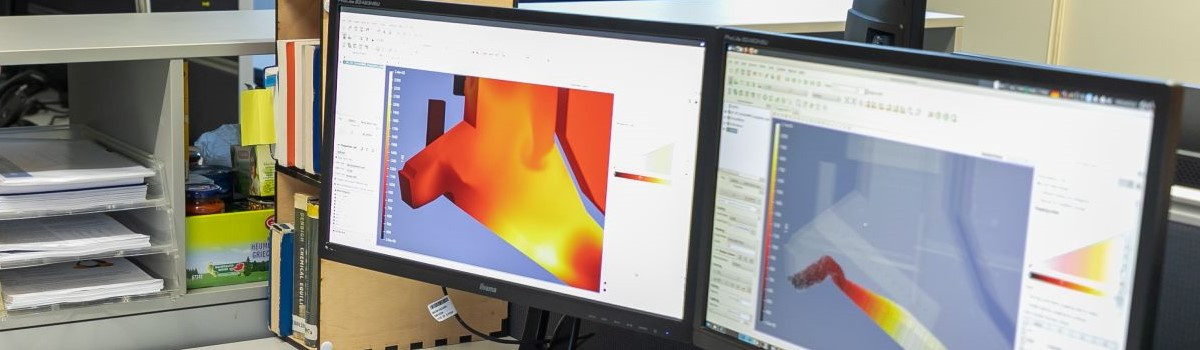

Currently, we are expanding our 3D CFD models as well as our 0D/1D models for chemical looping processes in fixed bed and fluidized bed gas generation plants. In order to massively reduce the computational time of 3D CFD models, we are working on the acceleration of our existing CFD-based model portfolio by developing suitable neural network modules or tabulation routines. In addition, we transfer the obtained CFD results into 1D models/model networks for usage in commercial software programs such as IPSEpro.

Further, our existing comprehensive laboratory equipment and measurement infrastructure allows us to characterize biomass feedstocks, thermal conversion products and processes using chemical, physical, and thermal analysis techniques.

We offer an integrated, interrelated concept from plant design to model-based plant optimization. Within BEST, the models and analyses created support experimental prototype development, the development of new control concepts or digital twins, and life cycle assessment.