COMET-Programme

The strategic objectives of COMET are: developing new expertise by initiating and supporting long-term research co-operations between science and industry in top-level research, and extablishing and securing the technological leadership of companies. By advancing and bundling exting strengths and by integrating international research expertise Austria is to be strengthened as a research location for the long term.

The competence center BEST - Bioenergy and Sustainable Technologies GmbH is funded by BMIMI, BMWET and the federal states Vienna, Lower Austria und Styria within the scope of COMET - Competence Centers for Excellent Technologies. The program COMET is managed by the FFG.

As a link between academic research and industrial technology development, our vision is to develop and demonstrate sustainable and circular biorefinery processes and technologies for producing green gases, green liquid fuels, and green products, all of which will support the transition to a climate-neutral, zero-fossil-carbon economy. Consequently, the resource basis will be extended to include organic residues, wastes, and carbon dioxide. Conversion technologies will be enhanced or redesigned to ensure their efficient and economical operation, and to allow the value cycles based on new feedstocks to be integrated into the system. By using our excellent experimental facilities, ranging from lab to pilot and demonstration scale plants, our goal is to conduct applied research of the highest scientific quality.

We apply advanced digital methods for technology development, and for the basic automation, optimization, and monitoring of the operation of individual technologies and entire plants. With the help of holistic and technology-neutral planning tools, we ensure that biorefineries and energy supply technologies are optimally integrated into a sustainable, renewable energy system.

MODELS FOR THE FUTURE

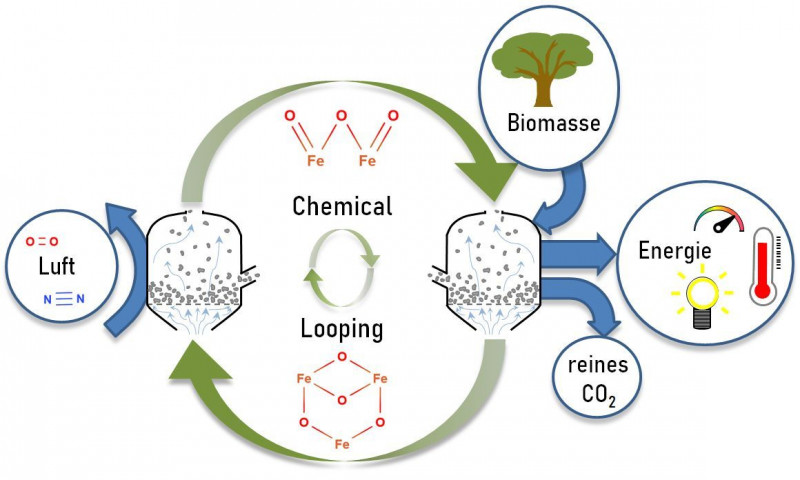

In the BIO-LOOP project, biomass as well as oxygen carrier particles are utilised during chemical looping processes. Therefore, modeling their converion plays a central role for simulating real-world applications in fixed bed and fluidized bed reactors.

With respect to the climate objectives Chemical Looping (CL) processes constitute a promising alternative to traditional thermochemical conversion routes. Through the application of solid materials, so-called oxygen carriers, instead of air as oxygen supply, CO2 can be easily separated from the flue gas. For example, biomass can be used for hydrogen production (Chemical Looping Hydrogen, CLH) or it can be burnt without CO2 emissions (Chemical Looping Combustion, CLC). The employed solid biomass and oxygen carrier materials consist of particulate systems which differ in size and properties depending on the application.

Multiple process scales have to be considered in order to describe the conversion of such particles. On the smallest scale, chemical reactions between gases and solids fundamentally take place. They are sufficient for modelling the conversion of very fine powders. However, in systems with larger particles (like for example pellets) gaseous reactants and heat first have to be transported to the outer surface and then into the particle. Compared to chemical reactions alone, this leads to an overall retardation of the conversion process.

For single biomass particles the existing, so-called Layer Model has been significantly improved. The original model described biochar reactions only at the outer particle surface. However, using the example of gasification, under typical conditions reactions take place in the entirety of the biochar layer. The new model considers the influence of transport phenomena on the conversion process while maintaining comparable computational performance.

Particles and Reactors

In real-world applications particles are used either in fixed bed or fluidized bed reactors. Additional efforts have to be made in order to describe the transport processes in the reactor as well as between reactor and particle. For this purpose, a reactor model and a particle model have to be coupled. The first simulation results show promise of a successful description of the overall processes. However, there is still a lot to be done. And after having reached the project’s half-time, we kick off the “second half” in a highly motivated manner.

Partner

- TU Graz (ITE, CEET)

- TU Wien

- NIC Ljubljana

- CSIC Spanien

- Chalmers University of Technology

- Aichernig Engineering GmbH

- AVL List GmbH

- Christof Industries Austria GmbH

- Rouge H2 Engineering GmbH

- SW-Energie Technik GmbH

- TG Mess-, Steuer- und Regeltechnik GmbH

- Rohkraft- Ing. Karl Pfiehl GmbH

Contact

Kai SCHULZE

kai.schulze@best-research.eu