COMET-Programme

The strategic objectives of COMET are: developing new expertise by initiating and supporting long-term research co-operations between science and industry in top-level research, and extablishing and securing the technological leadership of companies. By advancing and bundling exting strengths and by integrating international research expertise Austria is to be strengthened as a research location for the long term.

The competence center BEST - Bioenergy and Sustainable Technologies GmbH is funded by BMIMI, BMWET and the federal states Vienna, Lower Austria und Styria within the scope of COMET - Competence Centers for Excellent Technologies. The program COMET is managed by the FFG.

As a link between academic research and industrial technology development, our vision is to develop and demonstrate sustainable and circular biorefinery processes and technologies for producing green gases, green liquid fuels, and green products, all of which will support the transition to a climate-neutral, zero-fossil-carbon economy. Consequently, the resource basis will be extended to include organic residues, wastes, and carbon dioxide. Conversion technologies will be enhanced or redesigned to ensure their efficient and economical operation, and to allow the value cycles based on new feedstocks to be integrated into the system. By using our excellent experimental facilities, ranging from lab to pilot and demonstration scale plants, our goal is to conduct applied research of the highest scientific quality.

We apply advanced digital methods for technology development, and for the basic automation, optimization, and monitoring of the operation of individual technologies and entire plants. With the help of holistic and technology-neutral planning tools, we ensure that biorefineries and energy supply technologies are optimally integrated into a sustainable, renewable energy system.

THE RIGHT MATERIAL FOR NEGATIVE CO2 EMISSIONS

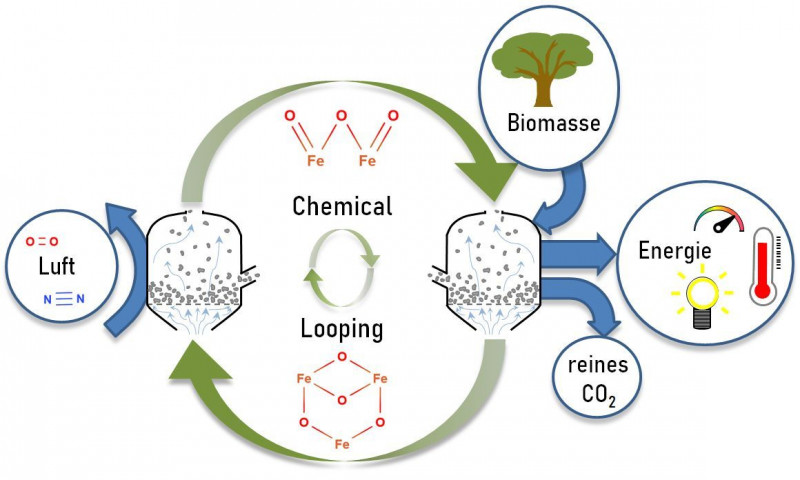

The aim of the BIO-LOOP project is to produce energy from biomass, while indirectly removing carbon dioxide from the atmosphere. The project team searches for an ideal osygen carrier for chemical looping combustion to achieve this aim.

Biomass is considered a CO2 neutral energy source and is already being used to reduce greenhouse gas emissions, since the CO2 released during combustion is absorbed from the atmosphere through photosynthesis during plant growth. Chemical looping (CL) represents a novel technology, where the oxygen required for the combustion (and also gasification) of biomass is provided by a solid oxygen carrier. The resulting CO2 can then be removed in a simple and cost-effective process and used as a valuable resource for further processing.

This CO2 negative emission technology thus makes a substantial contribution to the fight against global warming.

The oxygen carrier represents the key element of the chemical looping technology. Numerous analyses and experiments have been carried out as part of the BIO-LOOP project to identify the most important properties of oxygen carriers and the requirements they need to fulfil. These investigations helped to provide a clearer picture of their specifications and also resulted in the development of methods for assessing and comparing the different materials. This makes it possible to quickly assess the suitability of different metal oxides – be they natural ores or synthetic materials – for use as oxygen carriers.

Properties of oxygen carriers

In addition to environmental sustainability and costs, the materials investigated were experimentally evaluated based on two categories of key properties:

- specific oxygen carrier properties

- general bed material properties.

Only those materials that score top values in both categories provide an ideal oxygen carrier for use in chemical looping. The materials can be compared using so-called spider charts, where the area within the line directly reflects the material's suitability. The potential of each oxygen carrier is assessed prior to carrying out extensive experimental runs in a large-scale plant. Moreover, the reaction speed of the carrier material is measured using specific analysis tools in order to be able to model and simulate its behaviour in large-scale operation. The design can thus be optimised in advance, ensuring high efficiency in real-world deployment.

Impact and effects

The findings from this research project are expected to substantially accelerate the identification of suitable materials and thus the progress of the chemical looping combustion technology. This is of great importance in the fight against climate change, and it comes not a day too soon.

Partner

- TU Graz (ITE, CEET)

- TU Wien

- NIC Ljubljana

- SCIC Spain

- Chalmers University of Technology

- AFL List GmbH

- Christopf Industries Austria GmbH

- Rouge H2 Engineering GmbH

- SW-Energie Technik GmbH

- TG Mess-, Steuer- und Regeltechnik GmbH

- Rohkraft- Ing. Karl Pfiehl GmbH

Contact

Kai SCHULZE

kai.schulze@best-research.eu