Waste2Value-LevelUp

Waste2Value-LevelUp! deals with the conversion of biomass residues and waste into a synthesis gas using dual bed fluidized bed (DFB) technology. This is a sustainable alternative to incineration by converting solid residues into a hydrogen-rich and nitrogen-free synthesis gas.

The planning, construction, commissioning and initial test campaigns have already been successfully implemented as part of the predecessor project Waste2Value.

Introduction:

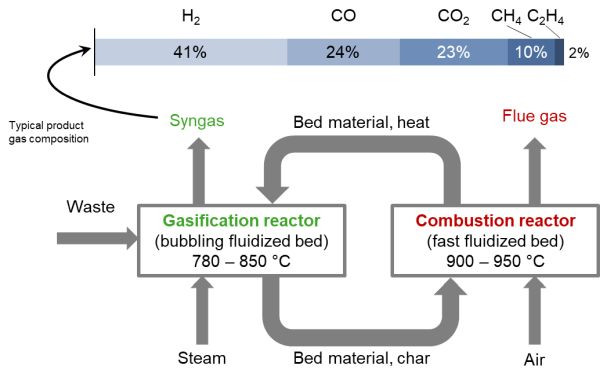

The underlying principle of DFB technology is the separation of endothermic gasification and exothermic combustion. The heat required for degassing and gasification is obtained by a circulating bed material between the combustion reactor and the gasification reactor. The currently used bed material is the natural mineral olivine, which also acts as a catalyst in the gasification reactor. Steam is used as the fluidization and reaction medium in the gasification reactor. The circulating fluidized bed in the combustion reactor is created by fluidization with air. The heat required gasification is supplied by combusting part of the degassed biomass.

The DFB technology was developed from the first generation with high quality biomass as input to the current second generation (advanced dual fluidized bed, aDFB) with residues and waste as input stream. The reactor design has been adapted to handle these more demanding residues. One of the most important changes to the reactor design was the introduction of a countercurrent column above the bubbling fluidized bed in the gasification reactor. This reactor design has already been successfully tested on a pilot scale (100 kW) at the TU Wien and is now implemented in the 1 MW demonstration plant of BEST GmbH at the Syngas Platform Vienna. The further expansion of the design beyond 1 MW is a central research topic of the Waste2Value-LevelUp!

1) Broadening the spectrum of residues and waste

- Sewage sludge incl. P-recovery (based on phosphate formation in ash fractions and heavy metal separation)

- Urban solid waste (fractionated and/or fuel blends)

- Industrial waste streams (rejects or on-site available residues)

- Fuel mixtures based on experimental case studies for specific industrial sites

2) Investigation of long-term effects (> 5 days) of inorganic matter in the system

- Catalytic activation from ash and additives (e.g. limestone) during steady-state operation

- Utilization of alternative bed materials in demonstration operations (e.g. feldspars)

- Ash accumulation and detailed analysis of different ash fractions (e.g. cyclones, hot product gas filter, flue gas filter, bottom ash and separated bed material)

- Deposit formation on heat exchangers and agglomeration tendency of bed material

3) Scale-up of the technology to industrially relevant capacities

- Reactor design incl. the scale up of the counter-current flow column

- Operation conditions using residues and waste

- Mass and energy balances for different industrial scales

- Evaluation of the coarse gas cleaning for different scales

Projektvolumen

EUR 5.000.000,--

Start of project

2023-04-01 (ongoing)

Supported by

FFG, COMET

Projektpartner

- BEST - Bioenergy and Sustainable Technologies GmbH, Sub-Area 1.3

- Universität für Bodenkultur (BOKU)

- TU Wien

- Technische Universität Lulea (LTU), Energietechnik, Abteilung für Energiewissenschaft

- Universität Umea

- Wien Energie GmbH

- Dieffenbacher Energy

- Österreichische Bundesforste

- Heinzel Paper

- Aichernig Engineering GmbH

- Solarbelt

- Yosemite Clean Energy

Contact

Matthias KUBA

matthias.kuba@best-research.eu

Area Management

Matthias Kuba

matthias.kuba@best-research.eu

Gerald Weber

gerald.weber@best-research.eu