BioHEAT: Development of a process chain based on opportunity fuels for heat production in industrial processes

Heat production in large industry sectors (steelmaking, cement production, etc.) is currently primarily dependent on fossil fuels. As the European Union has committed itself to be climate neutral by 2050, a shift in heat production has to be realised over the next decades. Establishing bio-refineries based on opportunity fuels builds upon already partially developed technologies, which are available in pilot- and demonstration-scale. Thus, a realization of such process chains can be achieved already within the next decade.

By following a step-by-step technology development research, the current level of knowledge will be significantly increased and the data basis for further

development can be provided. Hence, the technological proof for gasification from pilot- to 1 MW-scale is achieved within this project, raising the technology from TRL 3 to TRL 5. Additionally, an online measurement for tar species will developed, allowing for easier performance monitoring. The investigations into the catalytic centers on bed material will give further insight in how to increase the efficiency of the whole process chain. A novel methanation technology (laboratory-scale catalytic methanation consisting of three polytropic fixed bed reactors with intermediate cooling) will be investigated which will be used for the investigation of the gasification product gas upgrading to bioSNG ready for the injection into the natural gas grid.

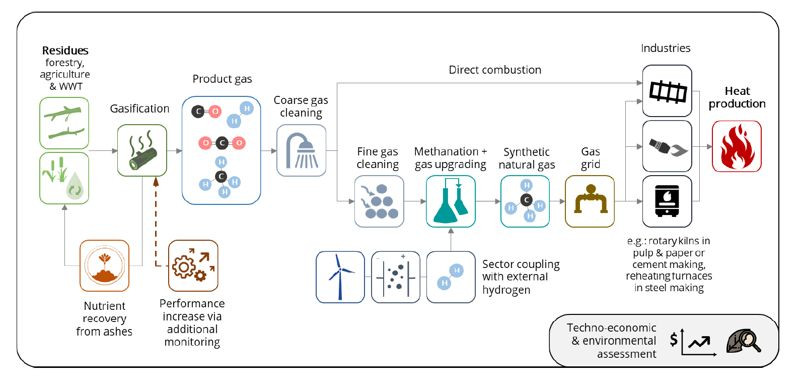

Two process chains utilizing biogenic biomass to produce heat for industry will be showcased. Especially the route via bioSNG provides a low barrier of entry since existing natural gas infrastructure can be use. In contrast, direct combustion of product gas can be implemented in industry burners with minimal adaptions to burner geometry. While bioSNG utilization offers a direct biogenic substitute for a fossil fuel, direct product gas combustion allows for an easier process chain to produce the energy carrier. Hence, the suitable process chain is dependent on the individual application and is evaluated by the techno-economic assessment.

The project aims the investigation of the utilization of bio-based opportunity fuels in DFB steam gasification and the further optimization of DFB steam gasification by optimized operation monitoring to produce a combustible product gas. Furthermore, the generation of bioSNG based on DFB steam gasification and subsequent combustion or methanation with a focus on a stable, load flexible and feedstock flexible operation is targeted. This leads to a technical and environmental proof-of-concept of the full process chain

Projektvolumen

EUR 1.350.000,--

Projektlaufzeit

2023-03-01 - 2025-09-30

Supported by

supported by ERA-NET / FFG

Projektpartner

- TU Wien, Institute of Chemical, Environmental and Bioscience Engineering

- Wien Energie GmbH

- Energy and Chemical Engineering GmbH

- Montanuniversität Leoben

- Jagiellonian University Krakow, Heterogeneous Reactions Kinetics Group

- Danex sp.z.o.o.

Contact

Miriam HUBER

miriam.huber@best-research.eu

Area Management

Matthias Kuba

matthias.kuba@best-research.eu

Gerald Weber

gerald.weber@best-research.eu