ADORe-SNG

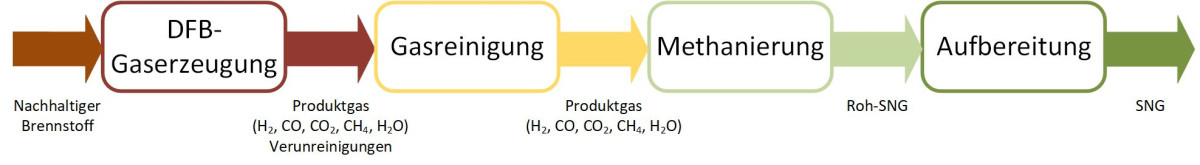

The CO2 intensity in the Austrian industry and energy sector can be reduced by the promising approach of generating synthetic natural gas (SNG) from renewable solid fuels such as residual and waste materials. The dual fluidized bed gas production technology with subsequent SNG synthesis was already implemented commercially. However, process development efforts have not yet addressed crucial issues, and the technology is not yet competitive and successful on the market. In particular the integrated process optimization, the development of a holistic control and automation concept, and the potential of digitalization of the technology have been insufficiently investigated.

The goal of this research project is not only to close the research gaps but also to focus on the interactions and possible overlapping areas between these research fields. Thereby, the full potential of the digitalization, automation and optimization of the process is exploited and a cost reduction at a high product quality is enabled.

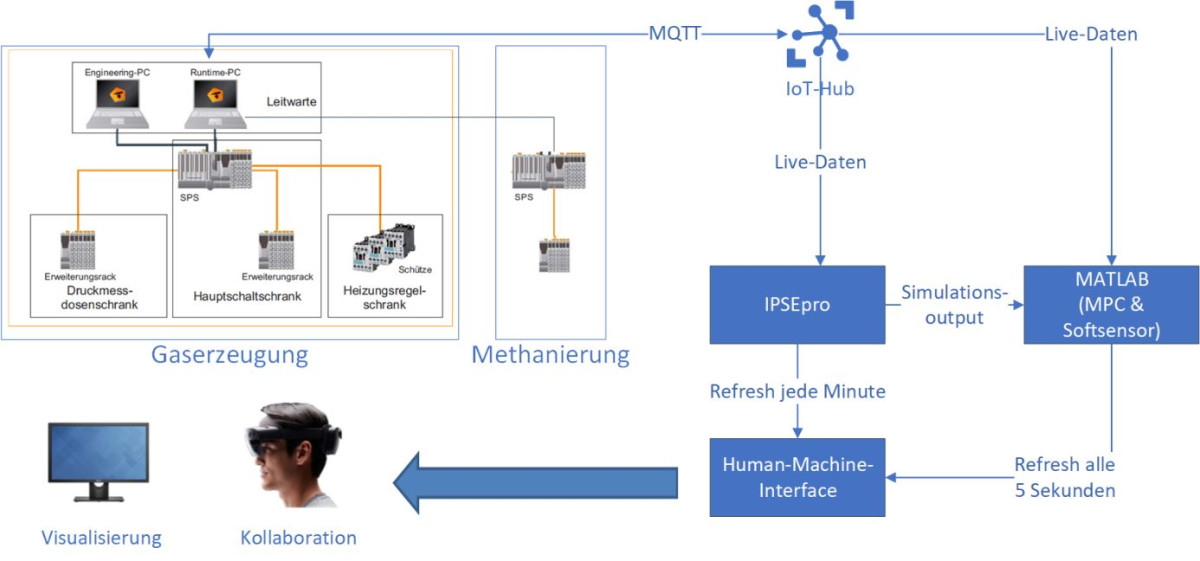

The process consisting of dual fluidised bed (DFB) gasification and fluidised bed methanation is modelled to enable overall optimisation (simulation studies, sensitivity analysis, scalability analysis). Based on these findings, a control concept is designed, integrated and tested on a 100 kW pilot plant, and the transferability of the R&D results to industrial plants is analysed using industrial measurement data.

The efficiency of data evaluation and process monitoring will be increased by creating a digital twin. This receives live data from the test plant and can visualise historical and current plant states and predict future ones using simulation models. This also includes the implementation of a soft sensor for measuring and forecasting the gas composition from product gas production and methanation.

For more information, please visit: https://projekte.ffg.at/projekt/3862075

The project was also nominated for the eAward2023

The objectives of the project can be summarised as follows:

- Process optimisation in process development: Optimisation of the SNG process chain taking into account the technical (yield, efficiency), economic (product production costs) and ecological (CO2 emissions) framework conditions

- Semi- or fully automated control and regulation of the SNG process chain through the use of model-predictive controllers, coupled with soft sensors

- Training and support for plant operators: support for plant operation, plant start-up, maintenance and training activities

- Process optimisation in commercial operation: increasing the number of annual operating hours and degree of automation by speeding up the commissioning process, optimising operation, detecting malfunctions and planning different operating modes in order to ensure economically and ecologically optimal operation (principle of "economic dispatching")

- Optimised planning documents with regard to automation and control technology for new plants: simplification of basic and detailed engineering of new plants

Projektlaufzeit

2021-04-01 - 2024-06-30

Supported by

This project is funded by the Climate and Energy Fund and is being carried out as part of the "Energy Research (e!MISSION)" programme (https://energieforschung.at/). Project number: 881135

Projektpartner

- Technische Universität Wien, Institut für Mechanik und Mechatronik (ARPA)

- https://www.mec.tuwien.ac.at/mechanik_und_mechatronik_e325/

- Zühlke Engineering (Austria) GmbH AG

- https://www.zuehlke.com/de

- BEST – Bioenergy and Sustainable Technologies GmbH

- https://best-research.eu/de

- Verto Engineering GmbH (VERTO)

- https://www.verto-engineering.com/?page_id=259

Projektleitung:

Ao.Univ.Prof. Dipl.-Ing. Dr.techn. Martin Kozek, martin.kozek@tuwien.ac.at

Projektkoordinator:

TU Wien, Institut für Mechanik und Mechatronik

Contact

Matthias BINDER

matthias.binder@best-research.eu

Area Management

Matthias Kuba

matthias.kuba@best-research.eu

Gerald Weber

gerald.weber@best-research.eu