Heat-to-fuel

Synopsis:

Heat-to-Fuel is a Horizon 2020 EU-funded project carried out by 14 partners from across Europe that aims to deliver the next generation of biofuel production technologies supporting the decarbonisation of the transportation sector. The project, coordinated by the Austrian institution Güssing Energy Technologies, started in September 2017 and will last four years. Heat-to-Fuel partners possess over 100 years of combined sectorial expertise and experience in the production of biofuels, and they’ll bring into the project the leading-edge demonstration facilities based on key industry and academic partners.

In numbers, Heat-to-fuel aims to:

- Deliver cost-competitive technologies achieving biofuel prices below €1 per litre. This is achieved by a 20% cost reduction in the biofuel production processes;

- Increase the quality of the biofuel resulting in 5% life-cycle green-house gases emissions reduction;

- Contribute to delivering goals of EU’s energy security by increasing the share of local resources used for producing energy, and thus reducing EU’s dependency of energy’s imports;

- Support local economies by generating 80-100 direct and 250 indirect jobs each time a new Heat-to-Fuel biorefinery is built;

- Prove the technological feasibility and economic worthiness of the concept acting as a catalyst of future industrial units.

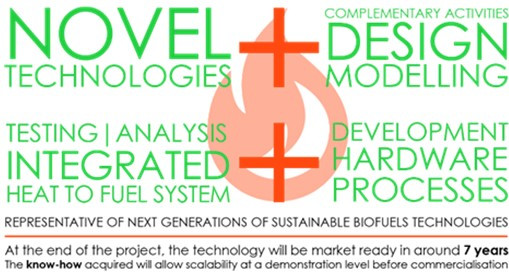

- These overarching objectives will be achieved thanks to the integration of novel technologies in Heat-to-Fuel together with innovative activities on design, modelling, development of hardware and processes, testing and life cycle analysis of a fully integrated system.

- At the end of the project, the know-how acquired will allow scalability at a demonstration level before commercialisation, representative of the next generations of sustainable biofuel technologies.

Scope and results of BEST GmbH within Heat-to-Fuel

Main task of BEST GmbH is in the planning, erection and operation of the world-wide first pilot APR (aqueous phase reforming) process demonstration unit based on the research results of POLITO obtained in laboratory scale. The used AP wastewater is a side product of the HTL (hydrothermal liquefaction) process. During the APR process hydrogen as well as side products (e.g. CO2) are formed. The provided hydrogen is used in the coupled Fischer-Tropsch process route to adjust the ratio between hydrogen and CO prior to the synthesis step. In terms of the Heat-to-fuel project a compact micro-structured Fischer-Tropsch reactor (provided by Atmostat/CEA) is used for the production of Fischer-Tropsch based advanced fuels.

BEST GmbH focuses on the demonstration of a world-wide unique process configuration (APR and Fischer-Tropsch) for the production of advanced fuels using HTL as well Fischer-Tropsch based wastewater for the provision of hydrogen for the synthesis step.

Projektvolumen

EUR 5.9 Mio. (Volumen BEST: EUR 515.000,--)

Projektlaufzeit

2017-09-01 - 2022-12-31

Projektpartner

- BEST GmbH - Area 2 (Fluidized Bed Conversion Systems), Austria

- Güssing Energy Technologies, Austria

- BETA Renewables, Italy

- IREC, Spain

- IChPW, Poland

- RECORD, Italy

- POLITO, Italy

- CRF, Italy

- CEA, France

- Johnson Matthey, United Kingdom

- Atmostat, France

- Skupina Fabrika, Slovenia

- R2M, Spain

Contact

Area Management

Matthias Kuba

matthias.kuba@best-research.eu

Gerald Weber

gerald.weber@best-research.eu