VergRestWert

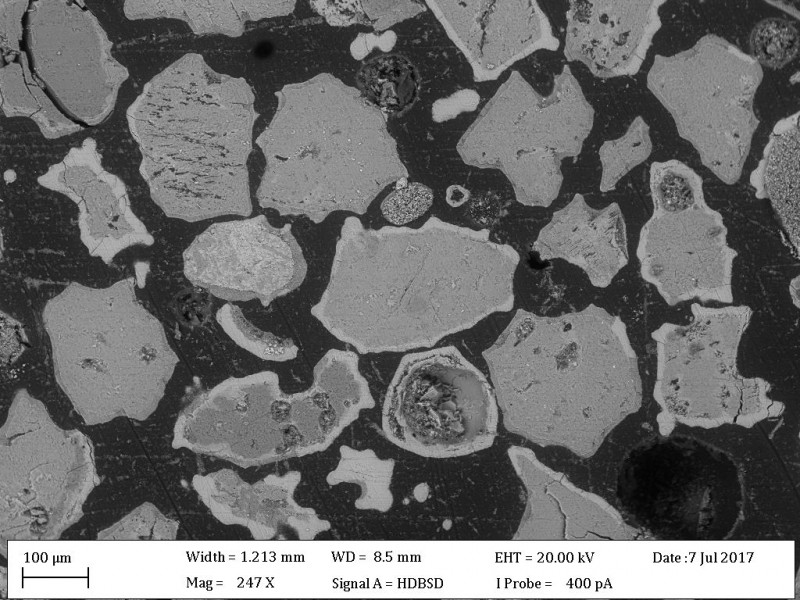

The project investigated the interaction between K-feldspar, a type of alternative bed material, and fuel ash from various biogenic residues. A further understanding of the underlying ash chemistry is of major importance to be able to better handle a wide range of feedstocks. It was found that K-feldspar interacts mainly through calcium substitution with potassium in the K-feldspar, whereas phosphorus-rich ash particles deposit as an outer layer with little direct interaction with the bed particle itself. Adding phosphorus-rich chicken manure to wheat straw as fuel reduced the bed agglomeration tendency by increasing the melting temperature of the ash produced and also shifted the interactions from the bed material surface to the ash phase. The results therefore emphasize that the fuel ash content is not a good indicator for ash-related problems, but rather an understanding of the underlying ash chemistry.

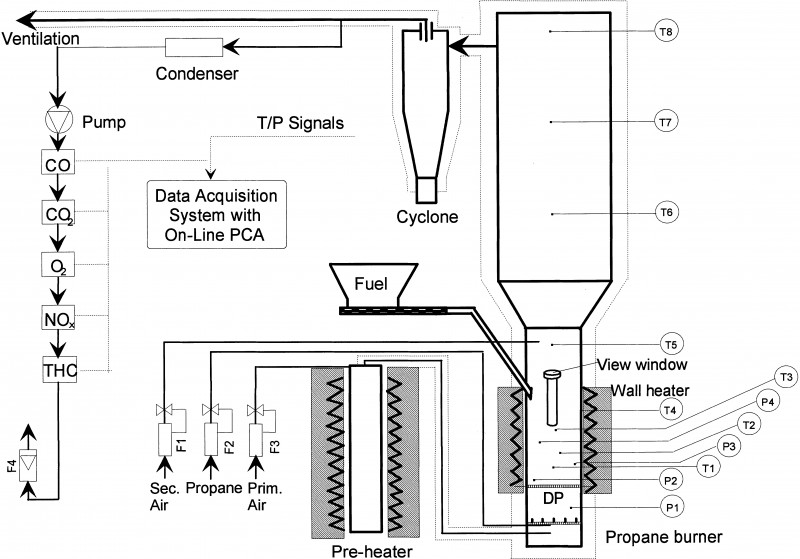

Studies on catalytic activity showed that the catalytic activity of K-feldspar regarding the water-gas-shift reaction clearly improved during the interaction with biomass ash. Higher amounts of ash in the fuel sped up the activation of the bed material. Gasification experiments performed throughout this project showed that the product gas composition is influenced by the catalytic activity of the bed material and by the ash content of the fuel. It was also possible to activate inactive bed materials with the addition of ash-rich fuels, leading to an improvement in gas composition over time. The problems observed during operation showed that an increased ash content has to be considered during operation. The continuous replacement of bed material is recommended to overcome bed material accumulation problems for ash-rich fuels.

The studies also further demonstrated the usability of K-feldspar as alternative bed material due to its reduced interaction with fuel ash compared to quartz, the typical bed material used in industrial fluidized bed combustion plants. Furthermore, it was possible to activate K-feldspar with fuel ash to be catalytically active regarding gasification reactions.

Projektvolumen

EUR 817.238,--

Projektlaufzeit

2016-04-01 - 2019-03-31

Supported by

FFG, COMET

Projektpartner

Contact

Katharina FÜRSATZ

katharina.fuersatz@best-research.eu

Area Management

Matthias Kuba

matthias.kuba@best-research.eu

Gerald Weber

gerald.weber@best-research.eu

![“Verfahrenstechnik : Vergasung und Gasreinigung.” [Online]. Available: https://www.vt.tuwien.ac.at/chemische_verfahrenstechnik_und_energietechnik/zukunftsfaehige_energietechnik/vergasung_und_gasreinigung/. [Accessed: 03-Aug-2017].](/webroot/files/image/Projektseite/Vergaser_TU%20Wien.jpg)