BIG - GreenGas: Industry project for innovative green gas production

The goal of the BIG - GreenGas project is to research new processes for upgrading biogenic residues into green gas, thereby enhancing the regional potential for climate-neutral gases in Austria. To this end, the regional availability of biogenic residues suitable for use in gasification was first determined. Selected residues were tested in a 1 MW gasification plant (Syngas Platform Vienna) for their suitability. The resulting product gas can subsequently be tested to produce synthetic natural gas (SNG) or hydrogen. Based on experimental data, costs for production chains can be estimated, an environmental balance can be created, and recommendations for adapting existing ÖVGW guidelines (e.g., limits for impurities developed with biogas in mind) can be given. The project runs for a total of three years, and the results of the first two project years are presented below.

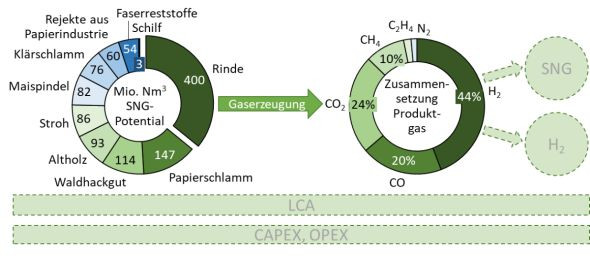

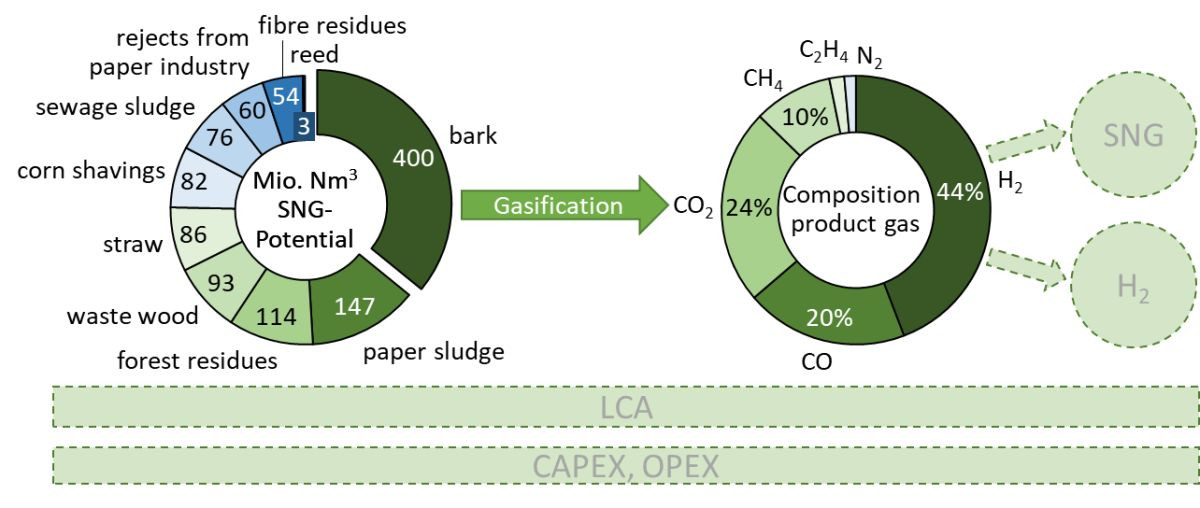

Results of the biomass potential analysis (left), achievable product gas composition of an optimised gasification with bark (middle), as well as the upgrading to SNG and H2 considered in the following years (right) and the ecological and economic evaluation (bottom).

Present results

The technical potential of the considered biomass assortments amounts to about 3.5 million t dry matter or 12 TWh CH4 per year. The wood-based assortments account for almost 55% of the calculated methane yield. Based on the surveyed biomass potentials, bark was selected as the first fuel for demonstration. Gasification with bark could be carried out successfully and the operation was comparable to previously used wood chips. Simulations of optimized operation at 1 MW demonstration scale showed a cold gas efficiency of 68% from fuel to product gas, and this without the use of fossil additive fuels. In the tested fine gas cleaning, it was also possible to remove tar impurities, allowing further use of the product gas for SNG and H2 production.

Based on the biomass potential, paper sludge was selected as the second fuel for a demonstration at the Syngas Platform Vienna. Due to its high water and ash content, a 3:1 mixture (based on wet weight) of paper sludge and wood chips was used. Gasification using paper sludge was successfully carried out, and the operation was also comparable to previously used wood chips. The operation was stable, and a H2:CO ratio of 2.3 was achieved. With further operational optimization, it will be possible to achieve the stoichiometric ratio of 3 for methanation in the future.

Cleaned and stored product gas was subsequently used to demonstrate the production of SNG from real product gas. For the continuous operation, it is essential that the catalyst is resistant to any form of deactivation (e.g., coking, abrasion, or poisoning). First, a parameter variation (temperature, specific residence time, H2O and H2 addition) was carried out to identify an as optimised as possible operating point for long-term operation. The operating point ultimately chosen for long-term operation (340°C, 1.3 Nl/g/h, 20 vol.% H2O, no H2 addition) promises a good raw SNG composition while simultaneously keeping the energy requirement for H2O evaporation low and having a low/medium risk of catalyst coking. Over a period of approximately 16 hours, constant raw SNG was synthesized during long-term operation with the chosen operating point. The gas composition always corresponded to that expected from the parameter variation, but with increasing test duration, a slight change could be observed in the conversion rate. Further investigations into the long-term stability of the catalyst are planned for the future.

In addition to the technical demonstration of producing green gases, a life cycle assessment (LCA) of the processes is to be created. Currently, this is available for wood chips and bark. For both feedstocks, the use of electricity contributes most to the global warming potential (GWP) of the feedstocks (wood chips 37%, bark 54%). For gasification using wood chips, wood chip production accounts for 32% of the GWP. Since bark is a residue the emissions from raw-material production are excluded and only emissions from drying must be considered. Additionally, relevant to the GWP are: RME for gas cleaning, transport, and amine for CO2 washing.

Outlook

In the final year of the project, the missing data (e.g., hydrogen production) will be generated to provide recommendations for an ÖVGW sustainability guideline for green gases. A further campaign with corn cobs has already been carried out for this purpose and is currently being analysed. Hydrogen separation from stored product gas is also being planned. The results obtained will be incorporated into cost and more detailed LCA evaluations, to determine the potential of gasification followed by synthesis for the Austrian gas network.

Projektvolumen

EUR 1,2 Mio.

Supported by

Das Projekt BIG – GreenGas wird gefördert von der FFG im Zuge der Ausschreibung „Collective Research“ unter der Projektnummer F0999891022. The project BIG - GreenGas is funded by the FFG in the course of the call "Collective Research" under the project number F0999891022.

Projektpartner

Contact

Katharina FÜRSATZ

katharina.fuersatz@best-research.eu

Area Management

Matthias Kuba

matthias.kuba@best-research.eu

Gerald Weber

gerald.weber@best-research.eu