FlexiFuelGasControl

Aufgrund der erhöhten Anstrengungen zur Reduktion der CO2-Emissionen gewann die energetische Nutzung von Biomasse in den letzten beiden Jahrzehnten zunehmend an Bedeutung. In der Forschung und Entwicklung lag dabei auch ein starker Fokus auf der Vergasung von Biomasse. Dabei wird die erneuerbare Biomasse zunächst in einem technischen Prozess vergast und das resultierende Produktgas anschließend zur Bereitstellung von Strom und Wärme genutzt. Für Anlagen im kleinen Leistungsbereich (kleiner 1 MW Brennstoffleistung) ist besonders die Technologie der Festbettvergasung von großer Bedeutung. Diese bietet die Möglichkeit zur kombinierten Produktion von Strom und Wärme (Kraft-Wärme-Kopplung) mit hohen Wirkungsgraden und geringsten Schadstoffemissionen in einem Leistungsbereich, in dem es selbst von Seite der wohl etablierten Biomasseverbrennung keine gleichwertigen Lösungen gibt. Allerdings limitieren strenge Anforderungen an die Brennstoffeigenschaften den robust-praktikablen Einsatz dieser hochmodernen Biomasse-Festbettvergasungsanlage. Zusätzlich stellen Einschränkungen im Lastwechselverhalten weitere Barrieren auf dem Weg zu einer Absatzmarktvergrößerung dar. Um die Flexibilität des Brennstoffes bzw. im speziellen das Lastwechselverhalten der Festbettvergasungssysteme zu vergrößern, ist eine signifikante Verbesserung der Regelung notwendig. Der vielversprechendste Ansatz dafür ist eine modellbasierte Regelungsstrategie, die alle Verknüpfungen und nichtlinearen Zusammenhänge, der unterschiedlichen Prozessvariablen, berücksichtigt.

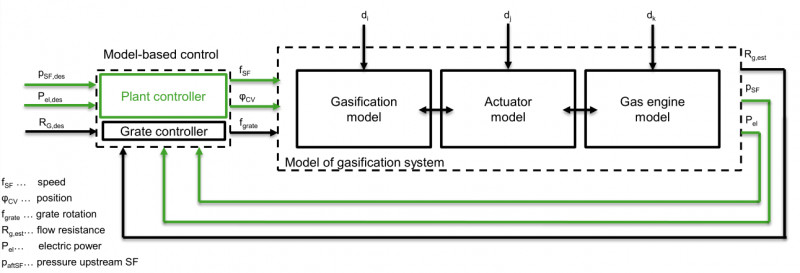

Im Projekt FlexiFuelGasControl wurde daher eine modellbasierte Regelungsstrategie für Biomasse-Festbettvergaser zur Verbesserung der Brennstoffflexibilität und der Lastmodulationsfähigkeit entwickelt.

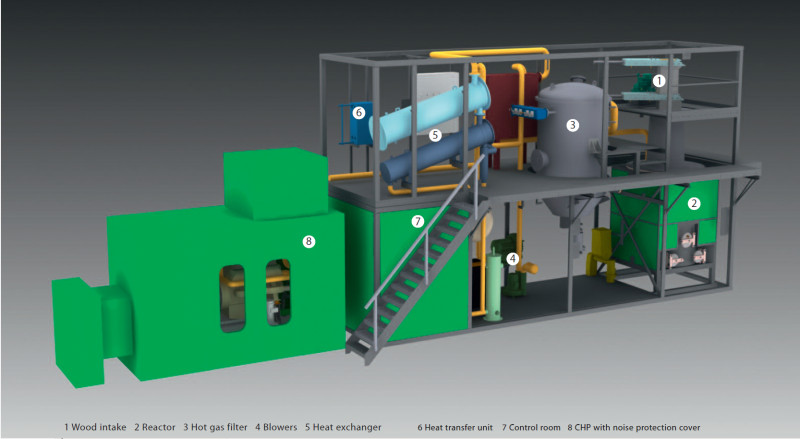

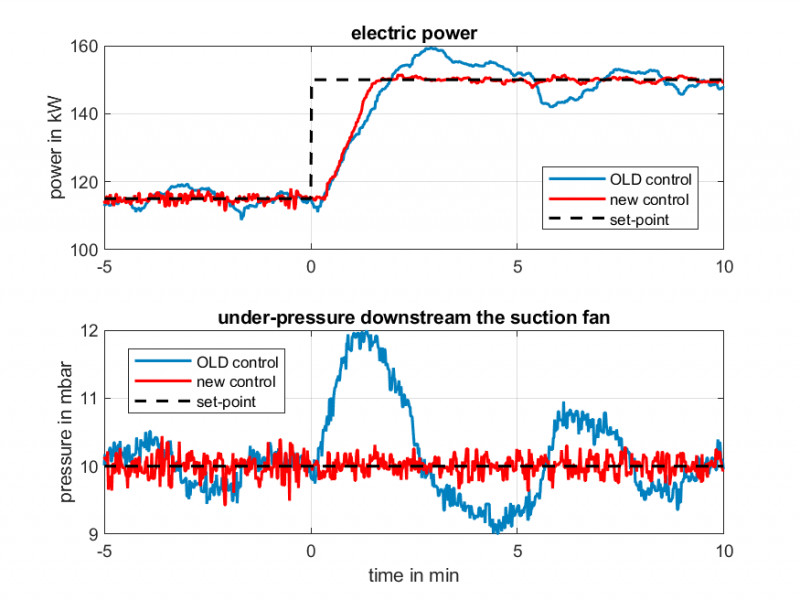

Die modellbasierte Regelung wurde für den laufenden Betrieb entwickelt und kann in einem Leistungsbereich von 110 kW bis 150 kW eingesetzt werden. Sie besteht aus zwei Teilreglern, einer Leistungsregelung und einer Rostregelung. Diese wurden an einer beispielhaften und repräsentativen industriellen Biomasse-Festbettvergasungsanlage implementiert und anschließend experimentell verifiziert. Dabei wurde gezeigt, dass die Lastmodulationsfähigkeit des Festbettvergasers durch die Leistungsregelung deutlich gesteigert und verbessert werden konnte.

Die erzielten Verbesserungen ermöglichen eine schnellere und robustere Änderung der elektrischen Leistung und bewirken somit eine Steigerung der Wirtschaftlichkeit sowie der Wettbewerbsfähigkeit der Biomasse-Festbettvergasung. Durch die Modularität kann die Regelung auch an weiteren Anlagen implementiert werden.

Projektvolumen

EUR 570.389,--

Projektlaufzeit

2017-03-01 - 2021-02-28

Finanzierung

FFG, Bridge - Frühphase 4. Ausschreibung

Projektpartner