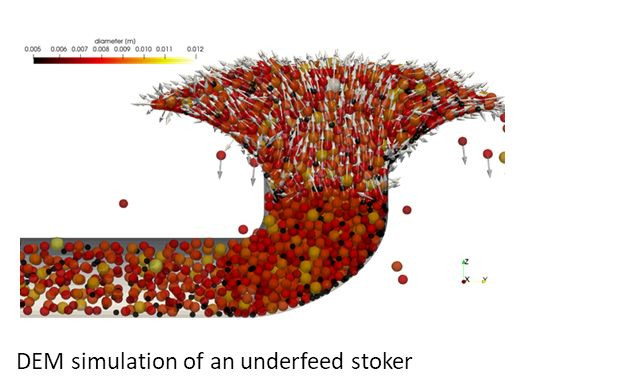

CFD simulation of biomass furnaces and boilers

The continuous reduction of dust, NOx, soot and CO emissions is still a central criterion in the new and further development of pellet and wood chip furnaces. CFD simulations are a suitable tool for carrying out both process parameters and geometric optimizations. Further advantages are

- higher thermal efficiencies of the plants

- lower material wear and higher plant availability

- reduction of development times and costs for test runs

- better understanding of the underlying processes

For this reason, an extensive, detailed CFD model (Virtual biomass combustion ) has been developed over the last 20 years at the Research Centre in cooperation with Graz University of Technology, which offers a high prediction quality.

In addition, special CFD modules necessary for the description of complex geometries such as tube bundle heat exchangers were created and can further be used for questions on deposition and fine dust formation as well as high-temperature corrosion processes.