BIO-LOOP: Chemical Looping for efficient biomass utilisation

Die Reduktion von Treibhausgasen ist eine der größten globalen Herausforderungen, denen wir uns heutzutage stellen müssen. Der Weltklimarat hat in seinem 2018 zur globalen Klimaerwärmung veröffentlichen Sonderbericht klar festgestellt, dass bis zum Jahr 2050 die Netto-Kohlendioxid-Emissionen auf Null herabgesetzt werden müssen, um die globale Erwärmung noch auf 1,5° C begrenzen zu können. Dies macht eine Entfernung des Treibhausgases CO2 (Kohlendioxid) aus der Atmosphäre notwendig, da in bestimmten Bereichen, wie der Landwirtschaft und der Luftfahrt, die Emissionen von Treibhausgasen nicht verhindert werden können.

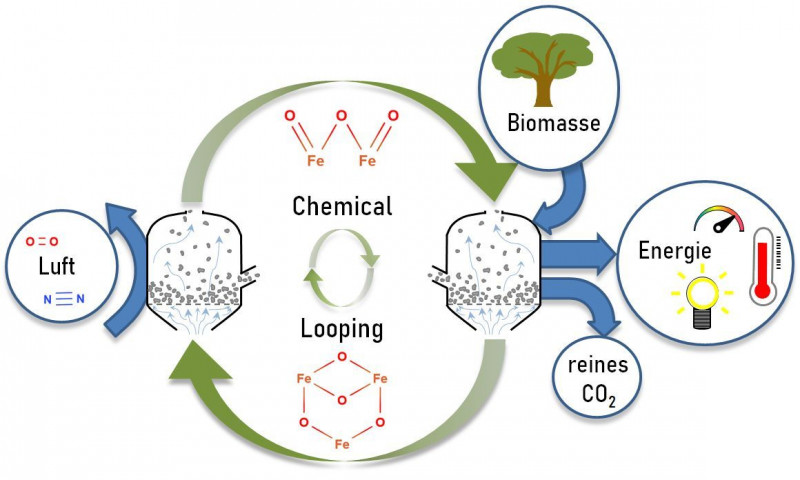

Biomasse wird schon jetzt als CO2-neutrale Energiequelle angesehen und daher zur Reduktion der Treibhausgas-Emissionen eingesetzt, da das bei der Verbrennung freigesetzte CO2 beim Wachstum der Pflanzen eingebunden wurde. Mit Hilfe einer neuartigen Technologie, genannt Chemical Looping (CL), wird anstelle von Luft ein Feststoff (Metalloxid) als Sauerstoffträger für die Verbrennung und die Vergasung von Biomasse verwendet. Das dabei freiwerdende CO2 kann aus dem Verbrennungsabgas einfach und kostengünstig abgeschieden und auch als hochwertiger Grundstoff für eine Weiterverarbeitung bereitgestellt werden. Mithilfe der Chemical Looping Technologie wird die Energiebereitstellung aus Biomasse damit sogar CO2-negativ.

Diese vielversprechende Methode hat im Bereich der Biomasse bis jetzt einen sehr geringen Technologie-Reifegrad. Das soll nun aber mithilfe des COMET-Moduls „BIO-LOOP“ unter der Leitung von BEST geändert werden. Dabei sollen verschiedene Varianten dieser Technologie untersucht werden, wobei es vor allem um die Produktion von Strom und Wärme, hochreinem Wasserstoff für Brennstoffzellenautos sowie von Gasen als Rohstoffe für moderne Biotreibstoffe und biobasierte Materialien gehen soll.

In den kommenden vier Jahren soll die Tauglichkeit der Chemical Looping Technologie für den Biomassebereich nachgewiesen werden und mit einer dafür entwickelten CFD-Simulations-Toolbox zur Prozessanalyse von Strömung, Temperaturen und chemischen Reaktionen technologisch beherrschbar gemacht werden.

Für BEST ist das Projekt BIO-LOOP ein wichtiger Schritt hin zur verfolgten Vision, innovative Technologien und Systemlösungen für eine nachhaltige biobasierte Wirtschaft und zukünftige Energiesysteme zu schaffen.

Mit BIO-LOOP festigt sich die langfristige Perspektive einer Gesellschaft, die frei von fossilem Kohlenstoff wirtschaftet. Eine solche Wirtschaft ist auch unbedingt erforderlich, um die Auswirkungen des Klimawandels abzumildern.

Die Durchführung des geförderten COMET-Moduls erfolgt in vier Teilprojekten. Gemeinsam mit BEST arbeiten hier renommierte Forschungspartner - unter anderem TU Graz, TU Wien und international anerkannte Institute - sowie Unternehmenspartner aus verschiedenen Branchen zusammen.

Sucess-Stories

Wasserstoff aus biogenen Reststoffen

Mit dem richtigen Material zum negativen CO2

Projektlaufzeit

2020-04-01 - 2024-12-31

Finanzierung

BIO-LOOP wird im Rahmen von COMET - Competence Centers for Excellent Technologies durch BMK, BMDW und dem Land Steiermark (SFG) gefördert. Das Programm COMET wird durch die FFG abgewickelt.

Projektpartner

- TU Graz (Institut für Chemische Verfahrenstechnik und Umwelttechnik)

- TU Graz (Institut für Wärmetechnik)

- TU Wien, (ICEBE)

- Chalmers University of Technology

- Spanish National Research Council (CSIC)

- National Institute of Chemistry, Slovenia

- Aichernig Engineering GmbH

- AVL List GmbH

- Rouge H2 Engineering GmbH

- SW-Energie Technik GmbH

- TG Mess,-Steuer- und Regeltechnik GmbH

- Rohkraft – Ing. Karl Pfiehl GmbH